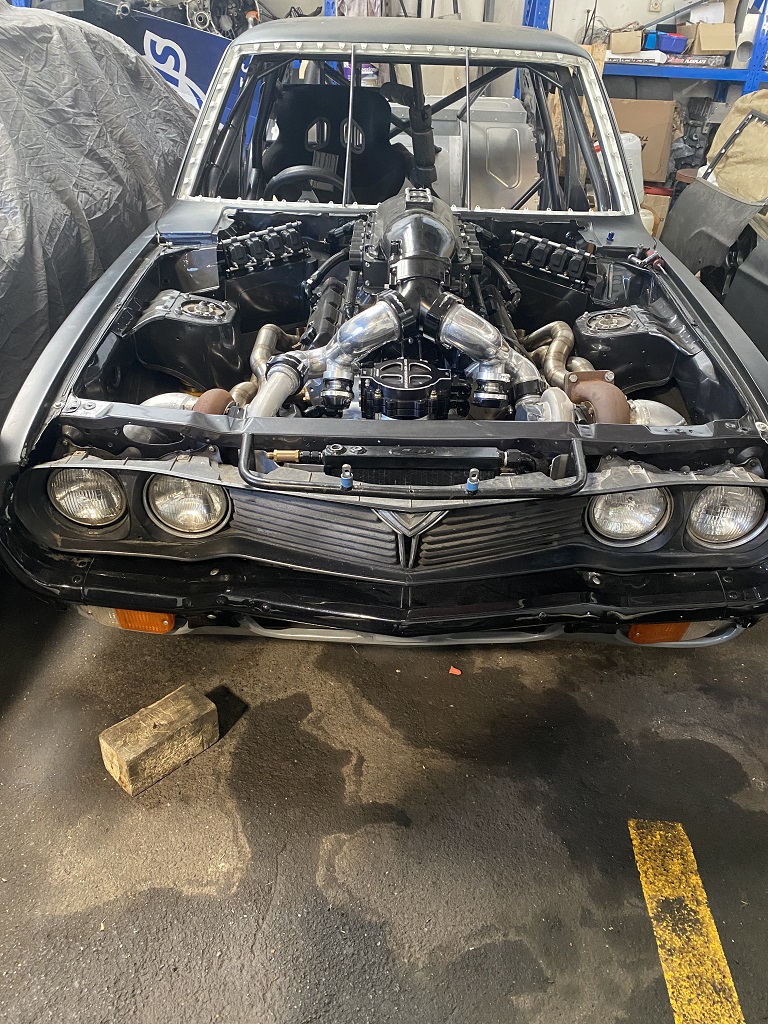

What was once a very competitive rotary powered RX4 drag car is being transformed into a monster by shoehorning an LS V8 engine and a couple of hair dryers with all the trimmings into its petite frame.

So one of my friends likes to go fast in a straight line and has finally decided that he should commit to a seriously built vehicle for the task and purchased this already well set up for the drag strip RX4.

With this platform he has asked me to assist with the metalwork to modify what is needed to make the LS fit, here is a bit of a list of the fabrication work.

- Modify the existing engine bay sheetmetal to fit the LS, mostly just cutting out to start.

- Modify the rear engine plate to accept the LS engine.

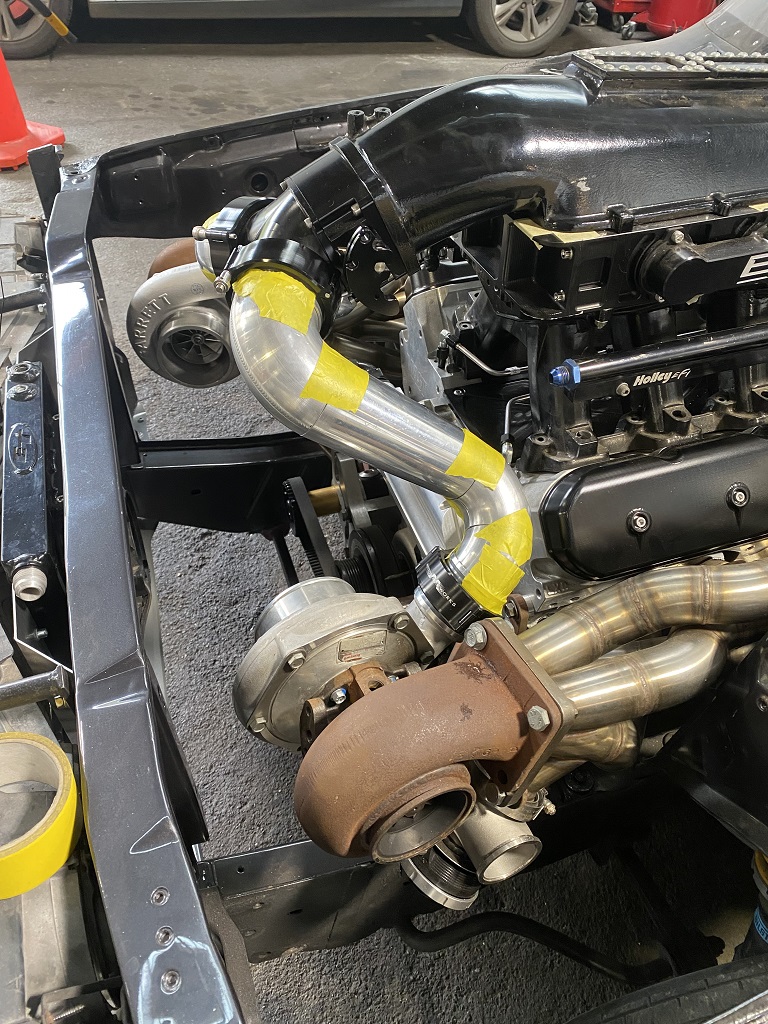

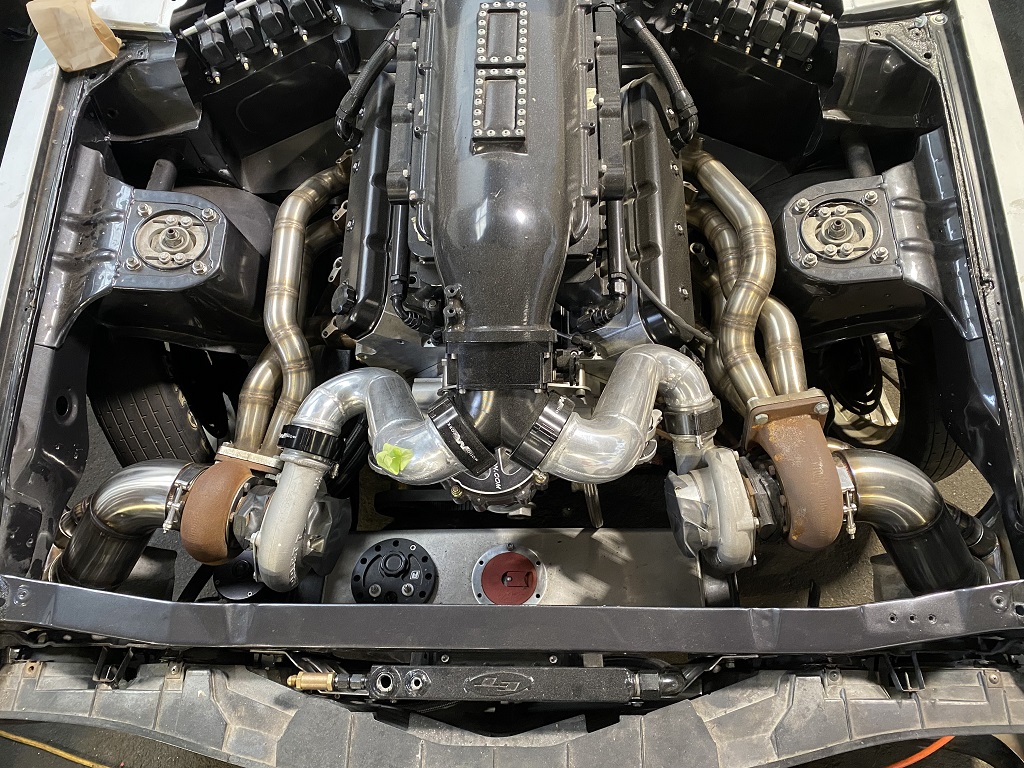

- Fabricate a set of turbo manifolds.

- Fabricate bracketry to support the manifolds.

- Fabricate and modify existing belt tensioning system.

- Fabricate an air intake and forward intercooler using supplied parts, this has since been swapped out for an intercooler that sits atop the engine.

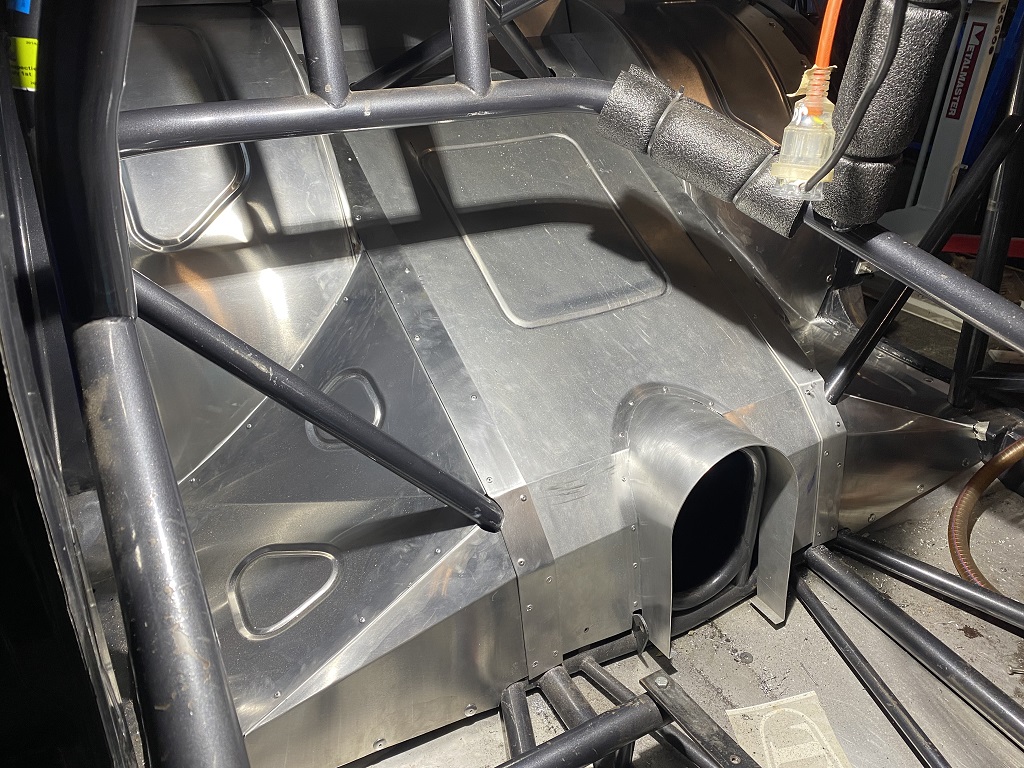

- Change the location of a section of cage that will interfere with his wheel selection.

- Modify the existing tubs to accept the new wheels and close in the rear with aluminium panels, some pre existing and some newly fabricated.

- Tidy up the engine bay ready for the panel beater/ painters to make it look good.

- Fabricate redesigned intercooler pipework for cold air intake

- Fabricate up front aluminium fuel tank

- Modification of front guards and incorporation of exhaust penetrations

- Design of mating flanges and fabrication of steering wheel extension

- Design of components required to add front wheel speed sensors

- Fabricate simple dash